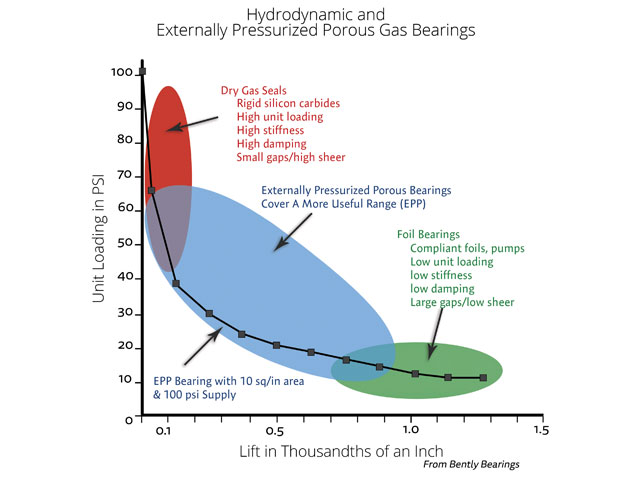

PROVEN Gas Bearing Technology

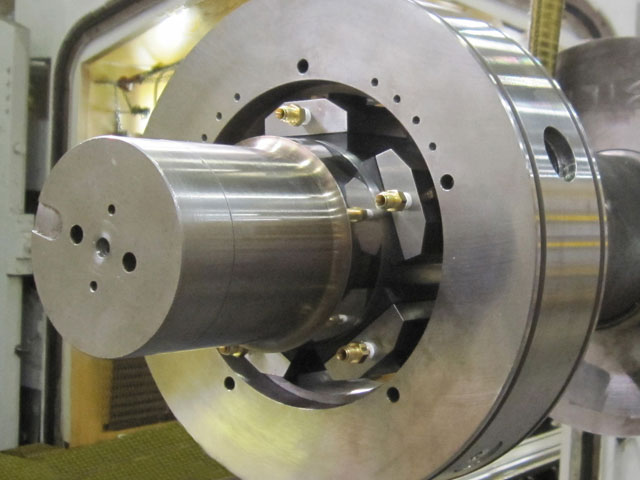

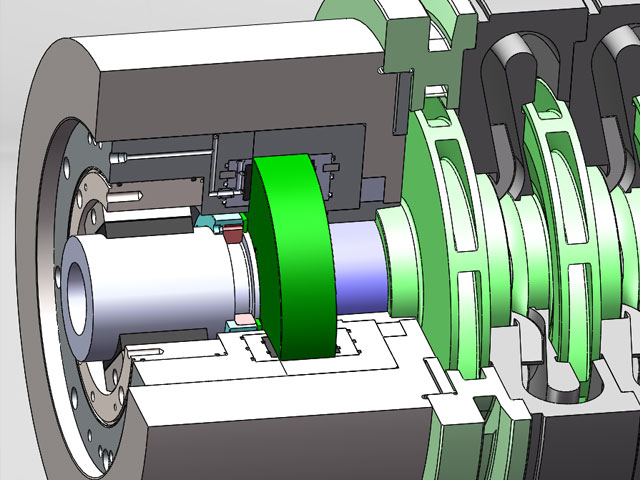

Externally Pressurized Porous (EPP) Gas Bearings for Rotating Equipment … using proven technology from New Way Air Bearings. New Way has over 25 years of experience selling bearings to metrology, machine tool, semiconductor, Formula one racing, and medical equipment builders. Bently Bearings is targeted to rotating equipment, both small, high speed machines where they replace foil or rolling element bearings and large turbines, motor generators, compressors, (where they replace oil hydrodynamic or magnetic bearings). EPP gas bearings have load capacities to 400 psi, can withstand temperatures compatible to 400C°, near zero friction, and near zero cross coupled stiffness. Bently Bearings enables innovative new equipment designs, and retrofits easily into existing equipment. Bently Bearings is revolutionizing rotating equipment.