Applications

Bently Bearings™ can be used in three main ways:

- As the primary radial or thrust bearings “in” rotating equipment

- On Balancing Machines

- To Assist with handling of rotating equipment during manufacturing

Radial or Thrust Bearings Used "in" Turbomachinery

Explore our best selling offers

Radial Bearings

Compressors, Turboexpaners, Steam & Gas Turbines, Pumps & Motors

Thrust Bearings

Compressors, Turboexpaners, Steam & Gas Turbines, Pumps & Motors

Bently BearingsTM thrust bearings can be used in place of conventional tilt-pad, hydrodynamic, oil-lubricated thrust bearings. Thrust features can be incorporated into balance pistons. Also, thrust bearings can also employ a sealing functionality, greatly simplifying sealing of compressors, pumps, and other turbomachinery.

Balancing Machines Balance Bearings

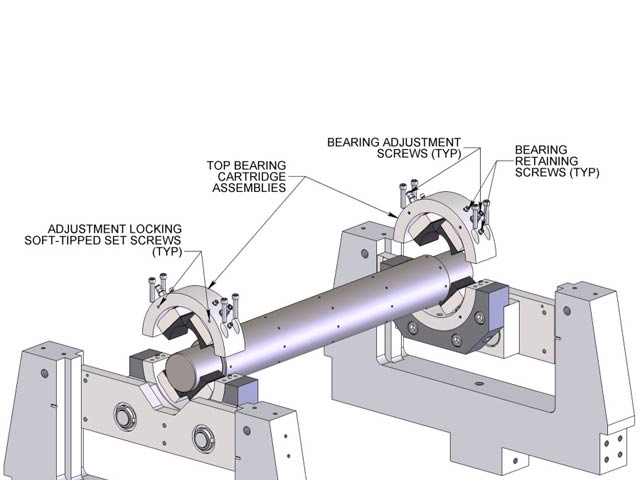

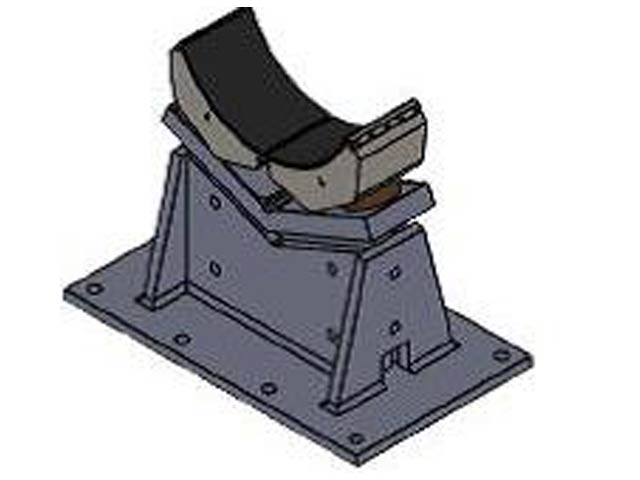

Adaptive Hardward to Retrofit Existing Balancing Machines

Balance Bearings can easily be adapted to existing balancing machines, resulting in a machine with many benefits, while enjoying cost savings of utilizing much of the existing balancing machine.

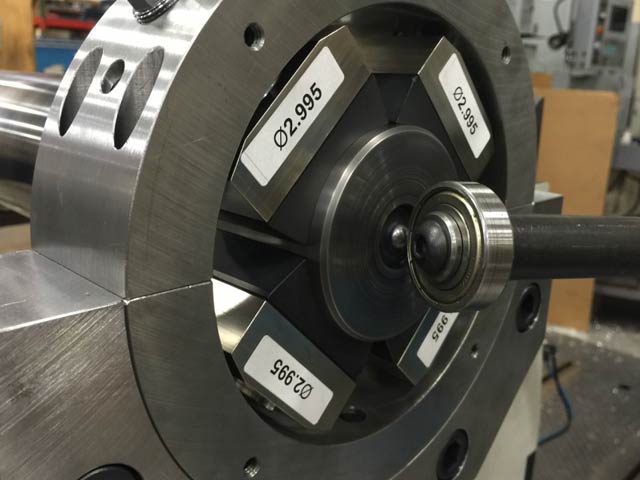

Balance Bearing - Benefits

Balance Bearings (patent pending) can be used on hard or soft mounted balancing machines. Key benefits include the prevention of damage to rotor journals (from hard rolls), reduction of audible and electrical noise in balancing operation, and a better axis-of-rotation which leads to improved balance.

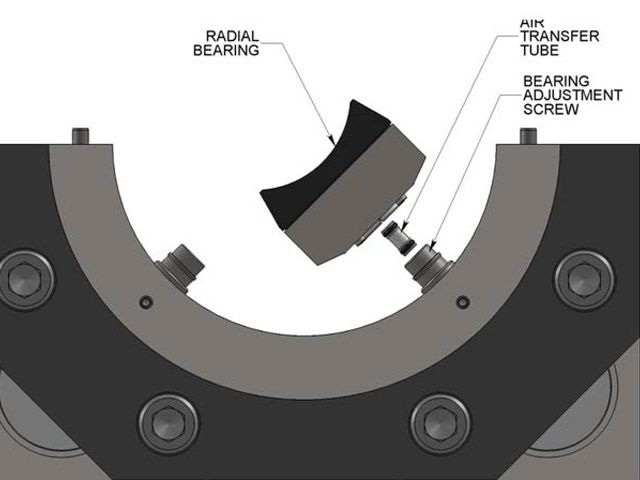

Snap Joint

The novel snap joing (patent pending) allows for input gas to the bearings to be plumbed directly through the joint. Also, the joint can pop-on and pop-off with ease.

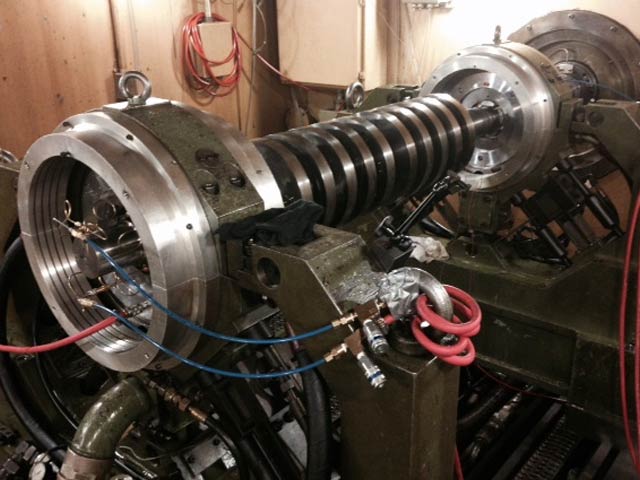

High Speed Balancing

High speed balancing using Balance Bearings can provide the benefits mentioned above, as well as eliminating the use of oil-lubricated bearings and supply systems in balance bunkers.

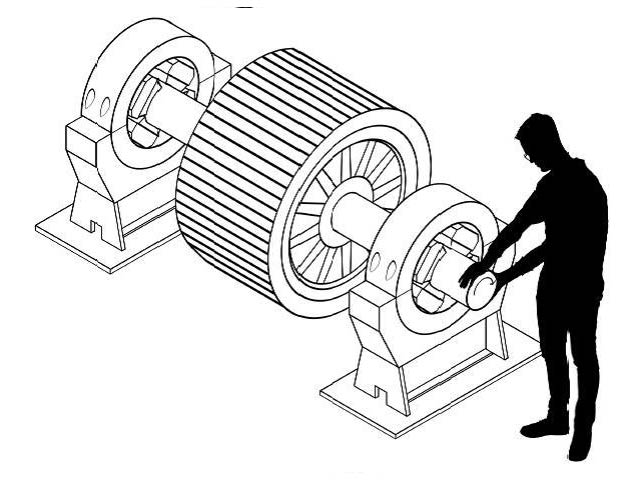

Handling of Rotating Assemblies During Manufacturing

Features & Benefits for Handling Ops during Manufacturing & Testing

- Uses Externally-Pressurized Porous (graphite) gas bearings to allow non-contact rotation and braking.

- Turning supply gas pressure “on” allows technician to easily rotate t=rotor (by hand) to desired position.

- Turning supply gas pressure “off” allows porous graphite gas bearings to lock rotor from rotating.

- Prevents marking on critical shaft diameters.

- Eliminates need for using a crane or other mechanical assists to lift/rotate rotor.

- Porous graphite bearing pads are extremely robust, and have extremely long life, even in dirty factory environments.

Ease-of-Rotation, Indexing, Braking

Applications:

- New rotor manufacturing or repairs

- Rotor winding operations

- Inserting copper bars into solid or stacked rotors

- Rotor insulation operations

- Rotor inspection operations

Supporting Large Rotors

Applications

- Machining operations

- Rotor inspection operations

- Indexing for repair operations